Here at Salloytech we provide technological solutions for the Thermal Spray facilities and aerospace industry.

Main activity of company is mechanical engineering but the big part of our

business is machining difficult-to-machine materials such as nickel-base superalloys and

titanium. Our speciality is the production of parts with restrictive quality requirements.

Have a look at our other services.

About Us

Salloytech company was established in 2014. We are engineering office with a production facility. From the beginning of our operation, the company focuses on quality assurance of manufactured parts.

From January 2018, Salloytech headquarter is located at the Science and Technology Park „Świerk” which is the part of the National Center for Nuclear Research in Otwock near Warsaw. Whole area is strictly protected because of the direct neighbourhood of a nuclear reactor ‘Maria’. Entrance to our office, warehouse and production floor is possible only via electronically controlled access zone. When working interdisciplinary projects we are able to take advantage of laboratories and experience of the engineers and scientists employed at the Institute.

Thanks to a team of certified specialists, the aerospace industry is the main customer of our services. Main activity of company is mechanical engineering but the big part of our business is machining difficult-to-machine materials such as nickel-base superalloys and titanium. The company's activity also includes rapid prototyping, reverse engineering and Non-Destructive Testing, work on development projects aimed at improving technological processes and consulting services in the field of quality assurance.

Our main strengths:

Quality

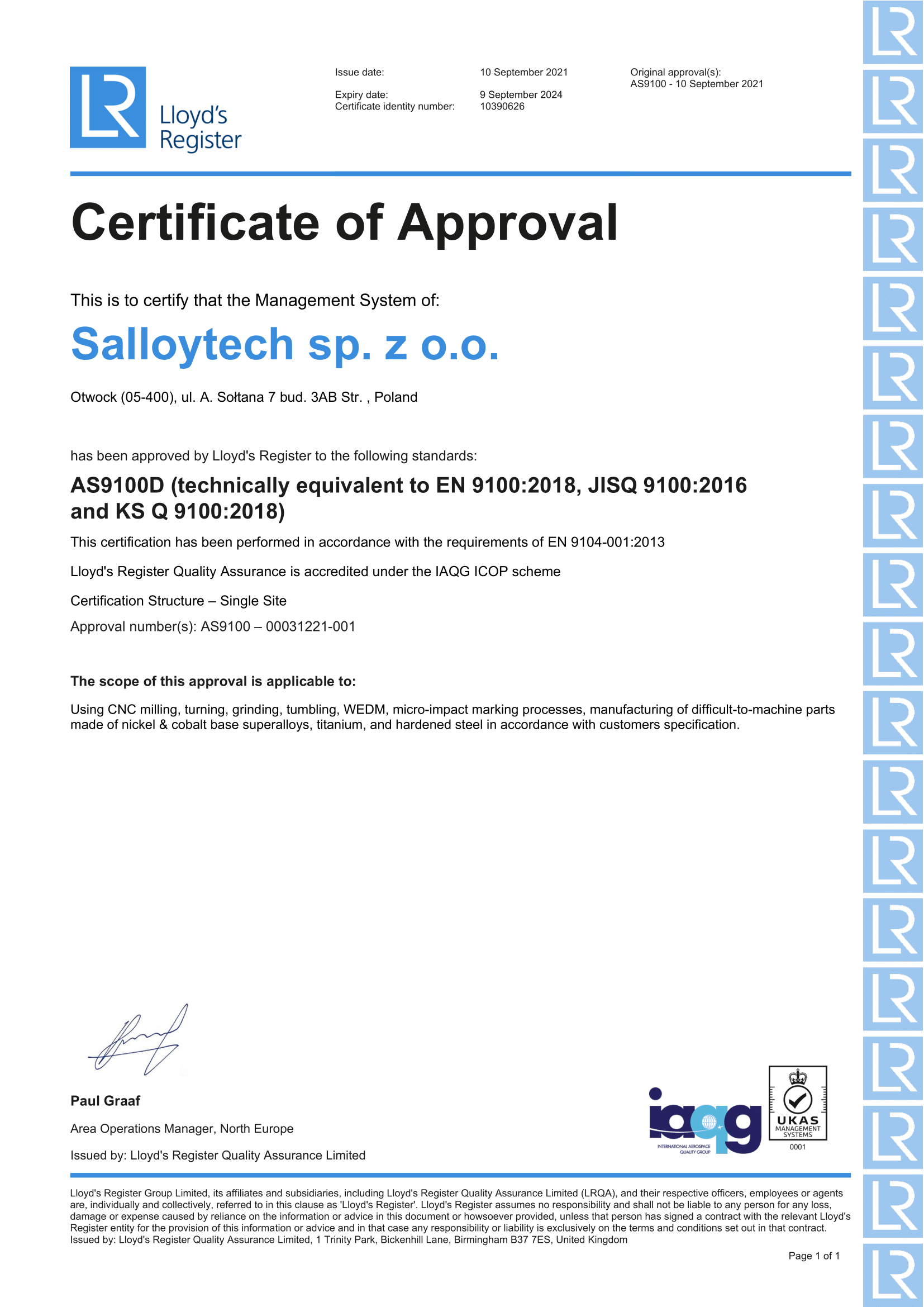

We maintain certfied AS9100D Quality Management System by qualified staff of internal auditors.

Technology

Using modern machining, loss and additive methods we ensure optimum price / performance ratio while meeting all requirements of the project.

Punctuality

Reliable processing from the design phase to the delivery to Customer through the Just-in-Time method.

Products

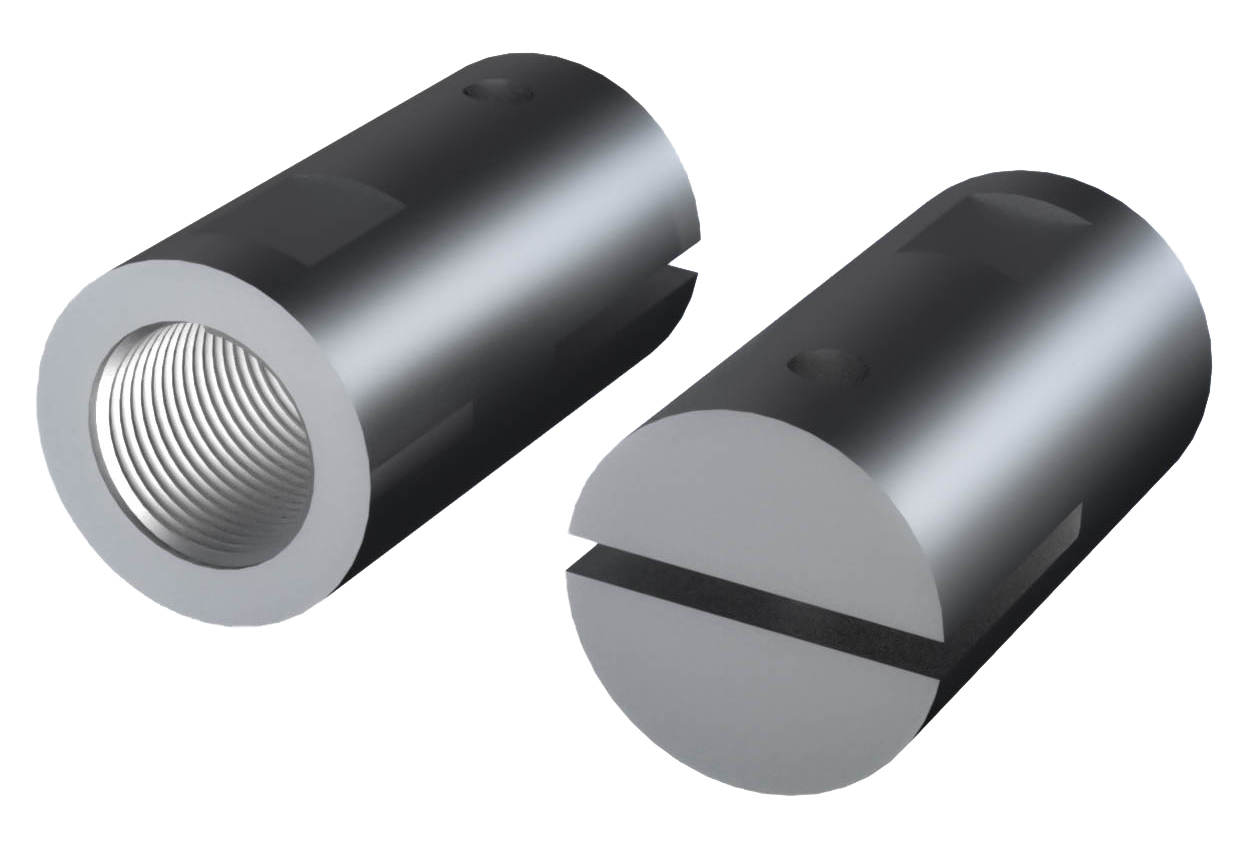

High-temperature Custom Metal Accessories

Salloytech is a one stop-shop for high-temperature custom metal accessories such as connection rods, couplings, grips, fixtures made of MAR M 246/247, Alloy 713C cast superalloys especially for Creep and Stress Rupture testing.

Other materials like nickel base single crystals (i.e. René N515) are available upon request. We supply the end product from the purchase of raw materials, through the heat treatment to machining. Our site is AS9100 certified, and the superalloys are mostly US origin to provide best possible performance. We can provide raw material samples to check its mechanical properties at elevated temperatures.

Specimens And Test Samples, Machined From Areospace Grade Materials

Salloytech manufactures high quality test coupons, specimens, samples, buttons, panels,

discs, and strips for Thermal and Cold Spray facilities mainly in the aviation industry.

We specialize in cutting difficult-to-machine aerospace grade materials such as nickel &

cobalt base superalloys, titanium, and hardened steel.

Our experience includes manufacturing specimens used for:

Test specimens manufactured by our developed technologies will allow you to:

We guarantee delivery of high quality and functional products as a result of:

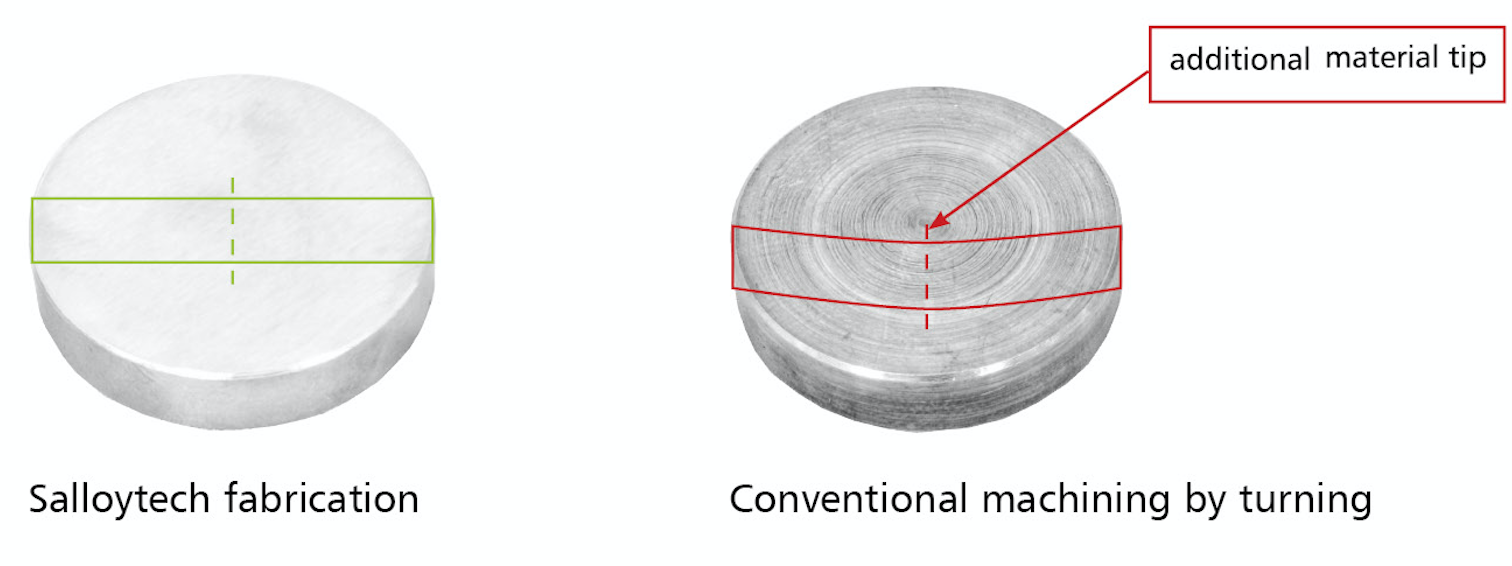

Test coupons also called “test buttons” for tensile / bond strength test of coatings are our flagship product. We know how many variables are in testing and we do our best to minimize their influence on the test results.

Thanks to our proprietary manufacturing process we can make test buttons with tight tolerances up to 0.0004 inch or 0.01 mm TIR of:

- flatness of flat surfaces,

- parallelism of flat surfaces,

- outside diameter,

and with:

- similar surface finish as the part,

for the good roughness correlation of the part and the specimen after grit blasting.

The results of the fabrication are:

TENSILE / BOND STRENGTH OF COATING TEST COUPON / BUTTON

Furthermore, our quality inspection staff check each one of them.

Why to use tight tolerance test coupons?

Thermal Spray facilities especially in aerospace industry often need to check coating quality on test specimens by destructive tests e.g. tensile / bond strength test. This need to be done for basically three reasons:

- to obtain approval for coating in qualification process,

- continuous monitor of coating consistency,

- decrease the frequency of testing according to Reduced Testing / Sampling procedure.

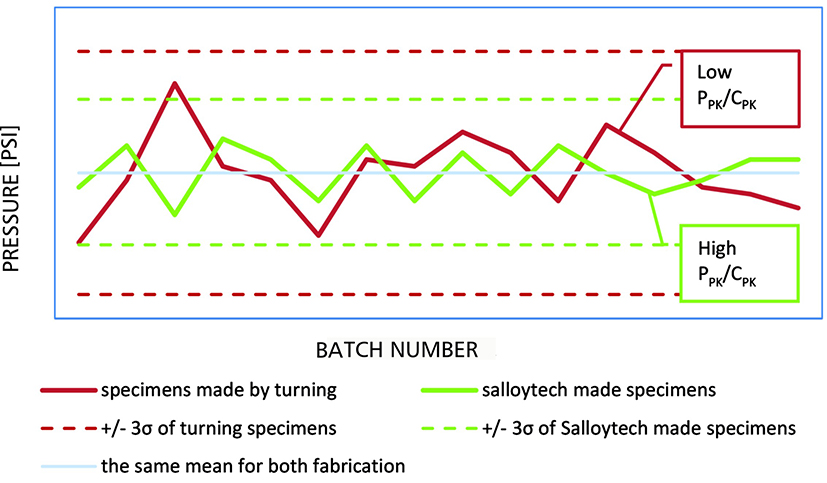

The acceptance or magnitude of above activities often depends on a process capability / performance index CPK / PPKcalculated with the test results during Statistical Process Control e.g. the more stable test results are the higher testing reduction can be obtained and maintained. There are many factors of test results variation but one of them is quality of test specimens – and here we have a solution for your facility. Using our made test buttons you can:

- obtain better test results for coating qualification,

- improve reduced testing and hold it on a high level.

Please see a visualisation on the graph below.

Brazing Accessories & Equipment

Salloytech supplies materials, accessories, products especially engineered for brazing process such as:

- Pre-sintered Diffusion Brazing Preforms (PSP) are a metallurgy products composed of superalloy and brazing powders from a customized blend. They are ideal for dimensional restoration as well as crack repair of blades and vanes subjected up to 1300°C in aero engines. Available in various compositions and shapes – e.g. plates, from 0.25 to 5 mm thickness can be cut to required dimensions. For difficult-to-reach areas it can be produce as a paste and paint. Thanks to low porosity (less than 2%), shrinkage is minimized thus only small allowance is needed for grinding/machining after brazing.

- Braze powders are produced by dry gas atomization. The process is capable to provide the particles that are clean and dry. They are spherical in shape and solid in structure. Powders are also uniform and homogeneous. From the chemical composition point of view, each particle contains required amounts of the alloying component.

- Braze paste is based on the blended braze alloy powders (metal fillers) and flux-free binder which is neutral for the brazing process.

- Braze Tape is a convenient form of an metal filler application. Consist of a uniform layer of cast braze alloy and a binder wound, packed in a rolls.

- Flux is a chemical compound applied to the joint surfaces before brazing. Its use, with a few exceptions, is crucial in the atmospheric brazing process. Heating a metal surface accelerates the formation of oxides, the result of chemical combination between the hot metal and oxygen in the air. If you don't stop these oxides from forming, they'll inhibit the brazing filler metal from wetting and bonding to the surfaces. A coating of flux on the joint area guards the surfaces from the air, preventing oxide formation. It also dissolves and absorbs any oxides that form throughout heating or that were not completely removed in the cleaning process.

- STOP-OFF in general is to prevents accidental brazing of mating surfaces and unwanted flow of filler metal.

- Brazing aids are also important parts of brazing process. It may be a blast media for preparing surfaces prior to brazing. Binder which can be mixed with any brazing filler metal powder to produce a paste for application with hand or air powered applicators. Or even Nicrobraz Cements which are used for mixing with brazing filler metal powders to ensure adhesion to base metal during handling and brazing.

Services

We invite you to view our full range of services:

Production

We specialize in the manufacturing of parts from superalloys (nickel base) and titanium alloys by using loss and additive methods. Processing of difficult-to-machine materials is our strong point. We also work with more conventional metal alloys such as aluminum and steel. Our machine park includes a range of machining such as CNC milling, turning, grinding, tumbling, WEDM, micro-impact marking, sandblasting and is constantly being expanded with manufacturing equipment. Other production processes, e.g. galvanic coatings, heat treatment, we are able to provide through controlled suppliers.

Services related to quality management

Consulting, audits, preparation for certification, training for implementation and maintenance of:

- Quality Management System compliant with ISO9001 / AS9100 and PRI AC7004 (NADCAP Aerospace Quality System),

- technological processes requiring NADCAP accreditation (specialization of Coatings PRI AC7109 - thermal spray, Coating Evaluation Laboratory, Stripping of Coatings, do not hesitate to ask about other processes),

- laboratories that meet the criteria of ISO 17025 and NADCAP (list AC7101),

as well as help in creating:

- control of the first article inspection (FAI) according to AS9102,

- control and technical plans for special processes.

Non Destructive Testing

We can perform X-ray testing using an industrial digital tomograph, which is at our disposal thanks to partnership with the Science and Technology Park as well as a cleanroom (ISO standard 14644-1) that can be used for example to can check cleanliness of the parts.

Rapid prototyping and 3D modelling

Thanks to our own resources and the laboratory infrastructure of the Science and Technology Park "Świerk" we can offer services related to the prototyping of metal and plastic parts (including silicone and rubber). We offer 3D printing from metal powders (max volume 90x90x72 mm) and plastic (max volume 250x210x200mm). We are able to design any 3D models (also optimized for 3D printing) in SolidWorks and Inventor software and also create technical documentation by qualified constructors.

Reverse Engineering

Using the Laboratory of Spatial Optical Scanner located in the Park structure, we can offer services related to reverse engineering by structural light scanning of the GOM ATOS Triple Scan device. The maximum working space is 560x560 mm.

Thermal processes - Plasma Spraying

Our experience in thermal processes, mainly in Plasma Spraying allows for comprehensive optimization from the side of:

- construction, in the design of technological equipment,

- technological, as an aid in the selection of the most favourable solutions to protect the part from overspray and sandblasting (masking),

- quality, we can offer coating quality assurance solutions, consultations when creating control and technical plans, conducting the first article inspection (FAI) and pre-audit for NADCAP accreditation.

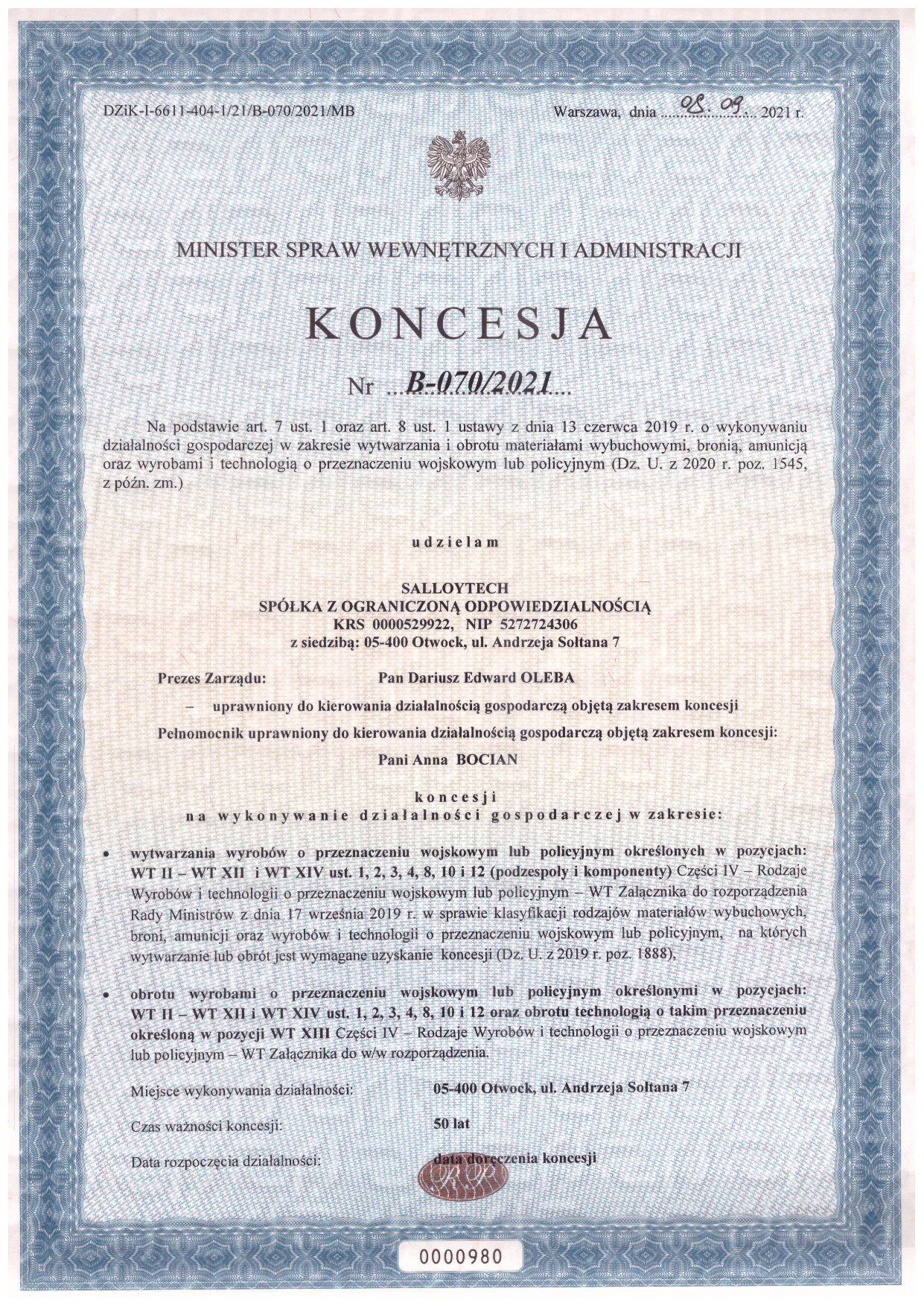

Quality systems, certificates, consessions

Vision:

To be a recognizable brand in the thermal spray and aviation industry on the global market.

Be not only associated with the manufacturing of parts under the customers purchase orders but also with innovative solutions that will bring many benefits to the contractor.

Mission:

Salloytech's mission is to meet the requirements of thermal spray and aviation industry customers by:

- new implementations of technological processes using developed know-how,

- machining of difficult-to-machine materials using modern and non-conventional manufacturing processes,

- continuous improvement of employees' qualifications.

Quality Policy:

Company Quality Policy is focused on the mechanical engineering projects and manufacturing of parts as well as the implementation of the best quality services, meeting the requirements of our customers. Salloytech is also focused on building lasting relationships with clients thanks to trust and a sense of mutual benefit.

The main assumptions and objectives of the Quality Management System are:

- customer satisfaction, which we achieve by timely execution of orders, providing products and services of the highest quality,

- manufacture of products with assured quality materials while maintaining an advantageous price thanks to cooperation with qualified suppliers,

- continuous development of infrastructure and improving working conditions by modernizing the production floor,

- constant improvement of our employees' qualifications thanks to the internal and external training program,

- high capability manufacturing processes through the implementation of new technologies and modernization of the machine park,

- optimization of materials costs by extending the range of suppliers,

- ensuring financial stability of the company by acquiring foreign markets and increasing production on domestic markets.

Awards

Mazowsze Provincial Government organizes “Innovator Mazowsza” annual competition and awards the best and the most innovative companies and scientists. Thirteen companies and forty two scientists took part.

Salloytech came in third in the category for manufacturing technology of metal working in nickel superalloys and titanium alloys with non-conventional methods and special processes for the needs of the aviation industry.

photo by Rafał Latoszek

Gallery

Products made by us:

EU Grants

The Salloytech company is implementing a project co-financed by European Funds under: